Elia Kimya is a company specialized in manufacturing and distribution of the well-known Aleppo Laurel Soap, with an experience exceeding 35 years. We started in the home land of laurel soap, Aleppo and we now continue our journey preserving this heritage in Turkey.

The soap has history going back as far as six thousand years. The earliest known soap recipe is credited to the ancient Babylonians around 2800 B.C. Arabic chemists were the first one to produce soaps made from vegetable oils, aromatic oils, and lye. Until this day, not much has changed in the manufacturing process of Aleppo Soap since. The oldest -still working- soap factory in Aleppo is more than 800 years old.

Soap is basically ( Animal or Vegetable Oil + Water + Alkalis ). Therefore, what determines the quality of soap is the oil used. Through decades of experience, vegetable oil was found to be far superior to animal, and the mixture of laurel & olive oils, superior to all other vegetable oils, due to their well-known countless medical and health benefits.

• Arguably the oldest populated city in the world, and

• have since been an important industrial centre.

• Abundance of laurel & olive oil (Basic raw materials).

• Perfect climatic conditions for Laurel & Olive Soap production.

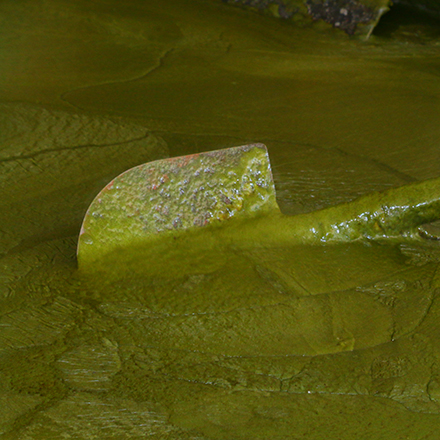

Aleppo soap should have a golden-yellow colour coating from the outside, which is gained from months of slow reactions under the sun and dry air. And a nature-green colour inside, which is gained from the mixture of olive and laurel oils.

It is tricky to determine the quality of a soap bar. Because any type of animal or vegetable oil, no matter its quality, with some colouring and perfume added, is enough to produce soap that looks and smells original. Therefore, besides referring to a chemical analysis or an experienced eye. There’s no method to determine wether a bar of soap is original or fake before use.

The skin naturally produces oil to stay soft and healthy. Throughout the day, dirt and dust stick to that oil causing skin to become ‘dirty’. Since water does not mix with oil, it cannot fully clean the dirty oil. The only way to do so is through soap molecules which fully isolate dirty oil from the skin causing the temporary dryness feeling as the skin reproduces new fresh oil. The same applies for the hair.

Chemical ingredients

Contains animal fat

Expensively produced and purchased

Environment non-friendly

Insufficient: dependable on the use of more products

Natural ingredients

NO animal fat

Inexpensively produced and purchased

Environment friendly

Sufficient: can alone be used for the face, hair, and body.

Aleppo Soap is ‘cooked’ with a method called the hot method. Aleppo Soap can’t be manufactured throughout the year, since it needs special weather conditions only available in the period between December and March, the rest of the year (till 7th) serves as a ‘resting’ phase for the soap in order to naturally get its colour, solidity and final shape. The method described below is the ‘Hot’ method, and it is as follows :

Oil, water, and Sodium Hydroxide/Salt are poured in precise amounts and a particular order into a large steam- heated bowl. Sequential heating and mixing are applied to the mixture until it reaches full saponification with the required colour and softness. This phase lasts between 20 to 48 hours.

The liquid soap is poured on a flat floor shaped as one or more large rectangles. A master/craftsman smoothens out the soap surface and flattens it to a desired thickness using a wooden device. The soap is then left for 24 hours to get basic solidity.

After acquiring basic firmness, the soap is cut with a plow-like device into square or rectangular shaped bars (pieces). Then the brand name is stamped manually on each soap bar using a hammer-like stamp.

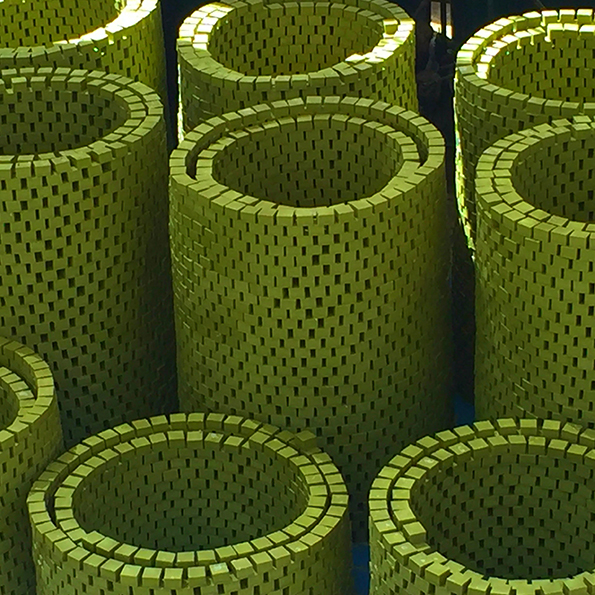

The soap bars are assembled together in a cylindrical or cubical manner, leaving an empty gap is between each two bars to create air tunnels that allow full wind exposure to each bar. The soap is then left for a period of approximately 6 months to fully dry up and take its final colour.

We can supply the requested amount of Aleppo Soap. We provide you with the open freedom to pick your options of :

For more information, feel free to contact us in the section below.

We always welcome new clients. Feel free to drop us a line. Send us an E-mail to :

info@eliakimya.com

or call us on :

COPYRIGHTS © 2015 | ELIA KIMYA CO.